Seamless Production Line Management

In modern manufacturing, every second counts. The difference between staying ahead or falling behind is often determined by how quickly and seamlessly you can adjust your production lines to real-world conditions.

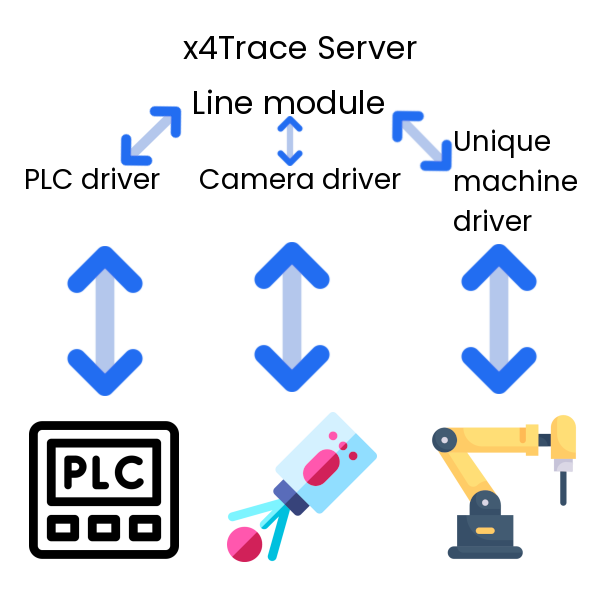

The x4Trace Line Handling feature is designed to give you full operational control and uninterrupted workflow continuity – from the first operation to the last handover.

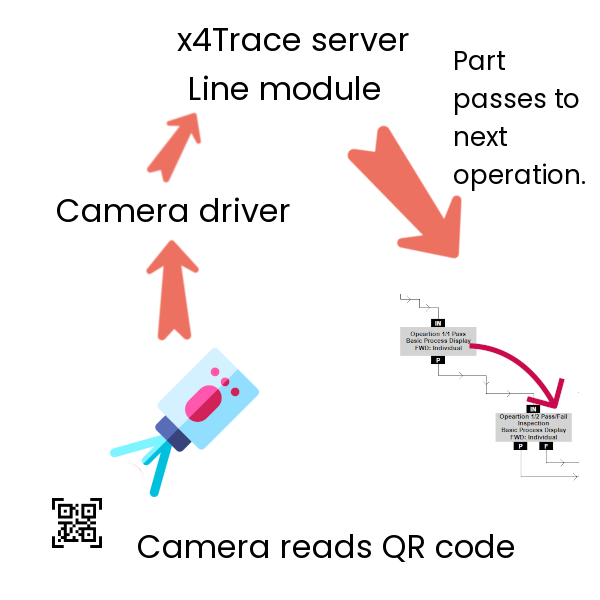

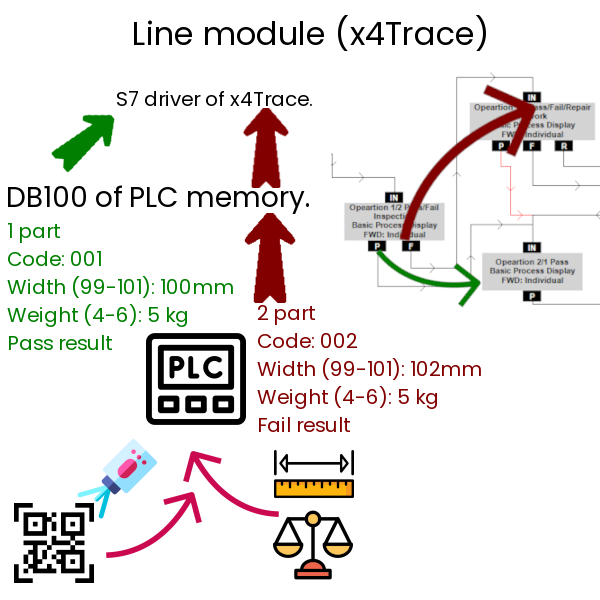

Automated Handover Logic:

Built-in intelligence ensures that each operation hands off to the next without delays. Configurable logic handles both sequential and parallel workflows, reducing idle time and bottlenecks.

Real-Time Line State Monitoring:

Track the live status of every operation, machine, and workstation. System dashboards visualize KPIs such as throughput, cycle time, and OEE (Overall Equipment Effectiveness) in real time.

Integrated Resource Management:

Works seamlessly with x4Trace Resource Designer to allocate machinery, tools, and personnel where they are needed most – automatically adapting to changing production priorities.

Terminal Integration:

Synchronizes with x4Trace Terminals for operator instructions, confirmations, and process validations, ensuring human actions are aligned with system logic.

Customizable Workflow Rules:

Supports bespoke logic, priority settings, and production constraints so that each manufacturer can adapt the system to their specific operational model.

Scalable Architecture:

Designed to support multiple production lines, plants, and geographies within the same control environment, with centralized or decentralized operation modes.

Data Traceability and Compliance:

Captures full operational data for each line event, providing audit-ready records for quality assurance and regulatory compliance.

Why It Matters

Implementing x4Trace Line Handling empowers manufacturers to:

React instantly to disruptions without compromising output quality.

Maintain seamless product flow from raw materials to finished goods.

Gain a unified, data-rich view of production health across all operations.

Improve OEE, reduce downtime, and streamline workforce coordination.

Whether you’re running a single production line or a multi-factory network, Line Handling acts as the central nervous system of your manufacturing environment – making your processes faster, smarter, and more resilient.Connected articles: