It is simple.

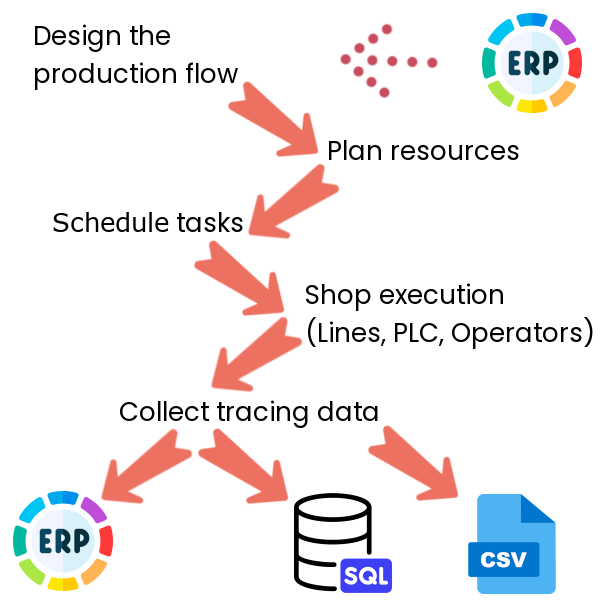

The most crucial part of x4Trace is the flow design and resource plan. The design of the product flow is the most fantastic feature. You can plan how the product passes production, which is represented by a flowchart. You make this flowchart, and x4Trace executes with production. The execution needs to plan the resources and schedule the tasks.The next step is the execution. You can involve the operators, lines, PLCs, and all devices in the shop. You can also do a fully automated execution. x4Trace controls the production, sends commands to PLCs, organizes the operators, guides the product’s path, and collects and stores data during the execution about the parts or the production (for example, batch number, assembled part IDs, or a heat sensor status while the part passed).While executing, x4Trace collects data, which can be forwarded to ERP or other systems. It also has a reporting tool, and the report result can be transferred.The production data (operations, runtime, product properties, etc.) can be from ERP, and when the manufacturing is done, the tracing data can be sent into the ERP system.