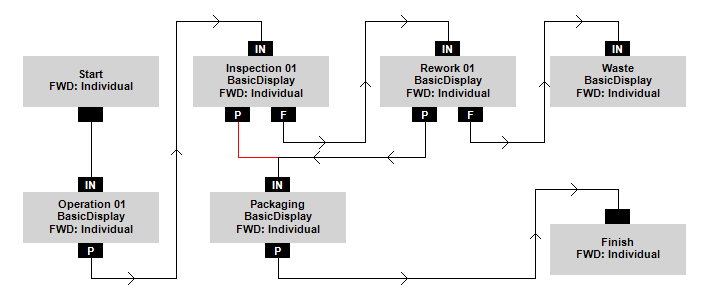

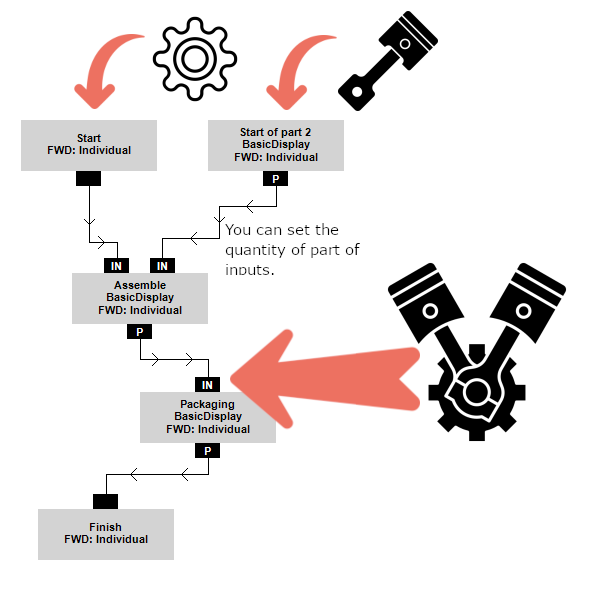

The flow is a flowchart of a product’s production. The elements are the operation, which can merge. x4Trace executes this flow with the shop, including all automated and manual operations. There are many settings for an operation. This sample shows you how a simple flow looks. This picture is a screenshot of the program.

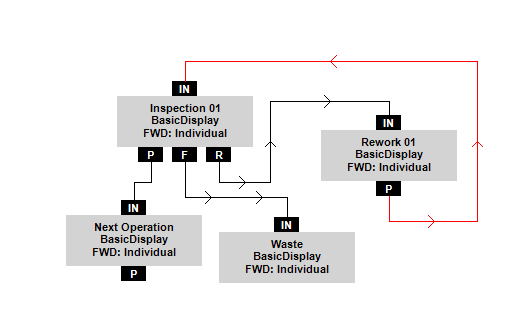

The operations have inputs and outputs. The parts are at the input of the operations, and the part passes on the output port corresponding to the result. Some operations have only one output: the pass result (OK/IO/Good). But some operations have more results (pass/fail/rework/etc.). The result can come from the operator, a PLC, or an inspection machine (you can connect third-party devices to x4Trace). This sample shows when the inspection result fails, the part is going to be wasted. When it is reworkable, it passes to the rework operation, and after the rework, it will be under inspection again. When the inspection result is passed, it is passed on to the next operation. This picture is a screenshot of the program.

The operations have inputs and outputs. The parts are at the input of the operations, and the part passes on the output port corresponding to the result. Some operations have only one output: the pass result (OK/IO/Good). But some operations have more results (pass/fail/rework/etc.). The result can come from the operator, a PLC, or an inspection machine (you can connect third-party devices to x4Trace). This sample shows when the inspection result fails, the part is going to be wasted. When it is reworkable, it passes to the rework operation, and after the rework, it will be under inspection again. When the inspection result is passed, it is passed on to the next operation. This picture is a screenshot of the program.

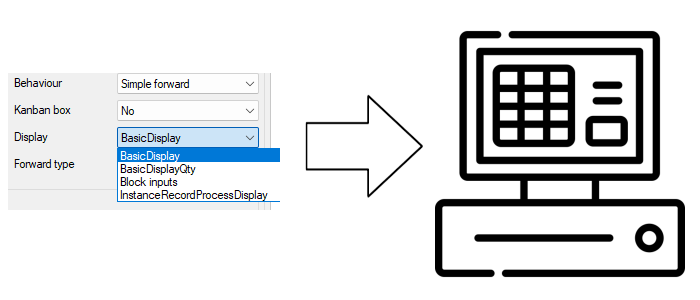

Operation is displayed when the operation starts on a terminal. You can select which display you want to use. Those are built-in displays, but you can add new displays. You need to know programming to add a new display, but this is a simple task. You can read about this under the integration subject.

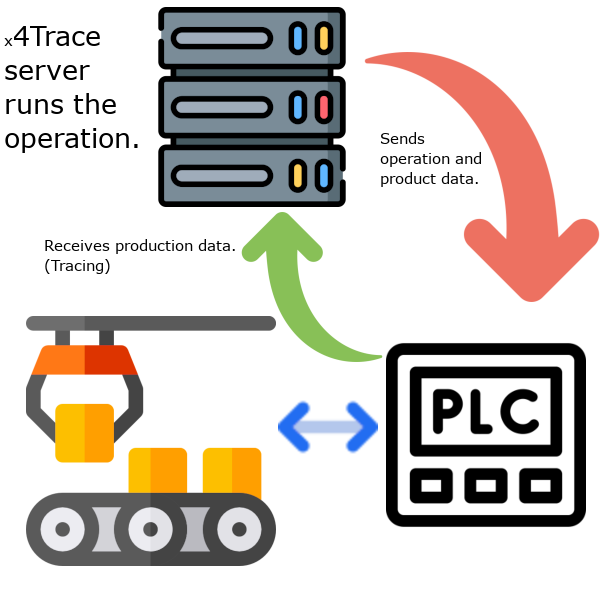

Line/division: You can select every operation’s line and division. This part of x4Trace handles the PLCs and the other connected devices. This function connects the operation and the devices of the line. The division is the list of the production devices and terminals. This is how to involve the line device in the production and tracing. x4Trace shares information with these devices and collects the production data.

Line/division: You can select every operation’s line and division. This part of x4Trace handles the PLCs and the other connected devices. This function connects the operation and the devices of the line. The division is the list of the production devices and terminals. This is how to involve the line device in the production and tracing. x4Trace shares information with these devices and collects the production data.

Variables: You can collect part data when it passes the operation. The data can be entered manually by the terminal or come from an external device, such as the PLC. Each operation can have separate data, and this is customizable.

Assembly: Parts/Components can be defined in the Order of production. These parts can be assembled with the produced product and can be determined by quantity or with a unique ID. x4Trace stores this information about the product when it passes the operation. The number of inputs of an operation is unlimited, and you can set the number of parts to assemble. On the sample image, this number is two.

Documentation: You can select which documents are visible on the terminal during operation execution. Uploading is possible in the product settings. The allowed format is PDF.

Connected articles: